Mentorship and supportive supervision improve management of laboratory commodities

Mentorship and supportive supervision improve management of laboratory commodities

![[Laboratory technician, Samuel Oule, discusses laboratory data with the facility in-charge, Dr. Denis Omiat, at Apapai Health Centre IV.] {Photo credit: MSH staff}](https://msh.org/wp-content/uploads/2020/04/lab_spars-715px.png)

The Apapai Health Centre IV laboratory in Serere district, Eastern Uganda, is busy today with ten patients waiting to have their lab tests taken. The laboratory technician, Samuel Oule, is confident that he has the right laboratory supplies to run tests for everyone he will see today—a welcome change from 12 months ago, when he would have had to turn some patients away because he lacked one or more needed laboratory supplies.

Lacking needed supplies was fairly common to Oule and others in Uganda. A 2016 survey of 120 Ugandan laboratories found that virtually all of them were stocked out of one or more of the supplies required to diagnose HIV, tuberculosis, malaria, and other common diseases.

Efficient and reliable laboratory services are an essential and fundamental component of any strong and effective health system, and diagnostic testing is essential for appropriate treatment and the rational use of drugs. The USAID-funded Uganda Health Supply Chain project (UHSC), led by MSH, is invested in improving the appropriate management and use of laboratory commodities, which directly contributes to better health outcomes and more efficient use of limited national resources.

Although a chronic funding gap for laboratory commodities is the primary reason for frequent stock-outs, there are other reasons as well. “We had no systems in place. Because our stock cards were not filled out correctly, we relied on guesswork to place our orders for laboratory items, and we often ran out of supplies,” says Oule. “Now we have enough supplies because we carefully track and record our commodities, know the minimum and maximum stock levels, and can plan orders and make timely requests based on actual consumption.”

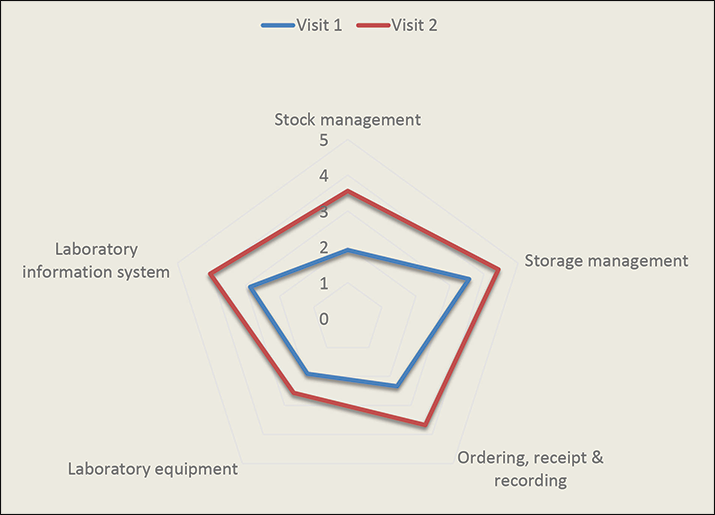

Oule’s newfound confidence is widely shared by his colleagues in the 292 health facilities that were part of the pilot test designed by UHSC and Uganda National Health Laboratory Services. Designed to resolve the root problems that can cause frequent stock-outs, the pilot intervention of the Laboratory Supervision, Performance Assessment and Recognition Strategy (SPARS) combines a supportive supervision approach with targeted performance assessments and recognition to improve the knowledge, skills, and practices of laboratory staff in five critical areas:

- storage management

- laboratory information systems

- ordering

- receipt and recording

- equipment management

Over the following 14 months, 42 trained district Lab SPARS supervisors assessed each facility’s performance in these five critical areas every two months and worked with the lab staff to develop and implement tailored, practical action plans to improve each facility’s weakest areas.

Sam Opio, the Lab SPARS supervisor for Apapai Health Centre IV, explains: “The purpose of the first visit was simply to unearth the issues. We observed the lab data was incomplete, inaccurate, and was not used in planning. There were poor reorder calculations.” The worst performing domain was ordering, and receipt and recording. According to Opio, “We discussed the challenges we identified, and cleaned and rearranged the lab and store. On subsequent visits, we reviewed the progress that had been made, and we encouraged staff. You need to push forward with everyone in the health facility; you can’t do it on your own.”

The number of stock-out days decreased markedly for some key laboratory supplies. The greater knowledge and improved skills in how to correctly maintain stock cards, to calculate the average monthly consumption of an item and the correct quantity to order, and to place orders on time shows success for this multipronged intervention and strategy.

Performance has dramatically improved in all 292 of the pilot facilities, over five Lab SPARS supervision visits. Whereas, the performance of “control” facilities—those facilities similar to those in the pilot study that did not receive Lab SPARS supervision visits—did not show improvements, the intervention strategy has had a significant effect on the stock management, storage management, ordering receipt and recording, laboratory information management, and equipment management practices at each health facilities.